- 201, 2024

Systems Spray-Cooled receives order from Hybar

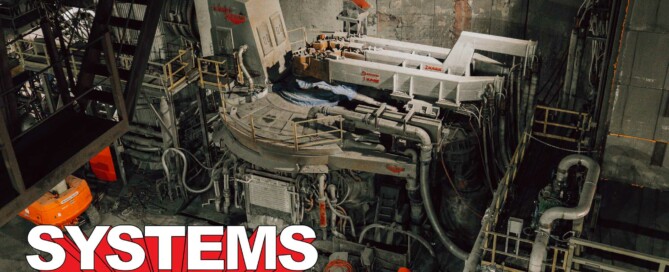

January 2024 Nashville, TN – Hybar, LLC has chosen Systems Spray-Cooled for the supply of Spray-Cooled™ EAF equipment at Hybar’s new rebar steelmaking facility located in Osceola, Arkansas. The new greenfield plant is being built on 1,300 acres in northeast Arkansas. The Spray-Cooled™ equipment will cover 100% of Hybar’s furnace cooling needs and will include

103, 2023Systems Spray-Cooled receives order from Nucor Steel West Virginia

March 2023 Nashville, TN –Nucor Steel Corporation has placed an order for new Electric Arc Furnace (EAF) equipment with Systems Spray-Cooled of The Systems Group for its greenfield sheet mill located in Mason County, WV. The Spray-Cooled™ equipment will cover 100% of Nucor Steel’s furnace cooling needs and will include the furnace sidewall, roof, and

112, 2022Systems Spray-Cooled™ receives order from Nucor Steel Lexington

December 2022 Nashville, TN –Nucor Steel Corporation has placed an order for new Electric Arc Furnace (EAF) equipment with Systems Spray-Cooled of The Systems Group for its recently announced micro-mill located in Lexington, NC. The Spray-Cooled ™ equipment will cover 100% of Nucor Steel’s furnace cooling needs and will include the furnace sidewall, roof, and elbow.

105, 2022Systems announces large expansion to El Dorado fabrication and machine shop, adding 60 new jobs

May 2022 El Dorado, AR – The Systems Group is pleased to announce a new expansion to their main fabrication and machine shop in El Dorado, AR. With the growth of Systems in all of their business units focused on the U.S. steel production industry, they will be purchasing 47 acres of land next to their

1002, 2022Systems installs and commissions new Spray-Cooled™ Electric Arc Furnace (EAF) equipment and a complete engineering package at EVRAZ Steel

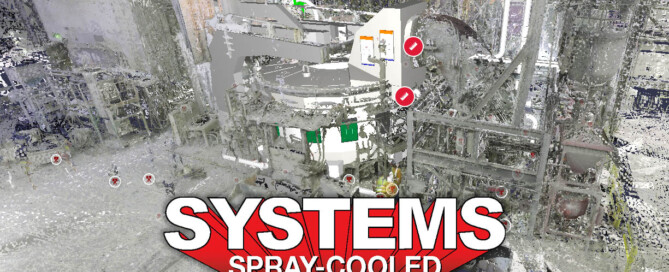

February 2022 Nashville, TN – The SYSTEMS Group, received an order from EVRAZ North America, for the installation of Spray-Cooled™ equipment at its steelmaking facility located in Pueblo, Colorado. The 2022 turn key project includes new spray-cooled Electric Arc Furnace (EAF) equipment and a complete engineering package that covers a laser scan of the entire

102, 2022Systems installs and commissions new Spray-Cooled™ Gravity Drained EAF Roof at Optimus Steel

February 2022 Nashville, TN – As part of its mill modernization upgrade that was completed last month, Optimus Steel, Beaumont, TX installed and commissioned a new Spray-Cooled™ electric arc furnace (EAF) roof and elbow with Systems Spray-Cooled. The design-build-install project includes a new EAF roof, elbow, engineering, laser scans, and accompanying equipment that will replace

2311, 2021Ovako Hofors Puts Safety at the Forefront with the First Spray-Cooled™ EAF Roof in the Nordic Region

July 24, 2017, El Dorado, Arkansas – Swedish steel producer Ovako has awarded Systems Spray-Cooled the contract to modernize and increase safety on their Electric Arc Furnace (EAF) with the first Spray-Cooled™ roof in the Nordic region, located at their bar, billet, tube, and rings facility in Hofors, Sweden. After first being exposed to Spray-Cooled

808, 2021NEW SMAC MINI PULSE-CLEANED AIR CLEANER OFFERS HOSPITAL GRADE FILTRATION FOR CRANE CABS

The Systems Group (TSG) has introduced a new pulse-cleaned industrial air cleaner that efficiently filters the inside of crane cabs for operator safety and comfort. Called the SMAC Mini, it is a compact version of the company’s Self-Maintaining Air Cleaner (SMAC), their flagship heavy-duty air filtration system for steel mills and heavy industry.

2506, 2021Systems Spray-Cooled installs and commissions a new Spray-Cooled™ EAF Roof and Elbow at Industeel Belgium

ArcelorMittal Industeel Belgium (“Industeel”) has installed and successfully commissioned a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof and Elbow with Systems Spray-Cooled of The System Group.

205, 2021Systems Spray-Cooled Recently Completes BRS Phase II Melt Shop Expansion

As part of its Phase Two expansion that was recently completed, Big River Steel in Osceola, Arkansas installed and commissioned new Spray-Cooled™ on furnace electric arc furnace (EAF) equipment including a roof, elbow, sidewall and off-gas duct work with Systems Spray-Cooled from The Systems Group.

612, 2020Systems Spray-Cooled receives contract from Nucor Steel Brandenburg

Systems Spray-Cooled™, of The Systems Group, was selected to supply the electric arc furnace (EAF) Spray-Cooled™ equipment to Nucor Corporation’s new plate mill in Brandenburg, KY. The new EAF greenfield project includes equipment for a single EAF operation.

1911, 2020Systems Contracting Advances 9 Positions – ENR Top 600 Specialty Contractors

Systems Contracting advances 9 positions to #341 in the 2020 Engineering News-Record’s Top 600 Specialty Contractors. El Dorado, Ark., November 19, 2020 – Systems Contracting Corporation, a leading contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking

1509, 2020Systems Spray-Cooled Delivers Equipment to Nucor Steel Gallatin

Systems Spray-Cooled Delivers Equipment to Nucor Steel Gallatin September 2020 Nashville, TN --Nucor Steel is expanding the steelmaking capacity at its flat-rolled sheet steel mill located in Ghent, KY. As part of the expansion project, Nucor is adding a new 175-ton EAF that will increase the mill’s annual capacity from 1.6 million tons to approximately

107, 2020Systems Spray-Cooled receives an order to upgrade Optimus Steel EAF

Systems Spray-Cooled receives an order to upgrade Optimus Steel EAF July 2020 Nashville, TN -- Optimus Steel has placed an order for a furnace upgrade solution with Systems Spray-Cooled of The Systems Group. The 4th quarter 2020 turn-key project includes a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof, a new Spray-Cooled™ Elbow, the accompanying equipment that will replace

106, 2020Systems Spray-Cooled receives order from Steel Dynamics, Inc.

Systems Spray-Cooled receives order from Steel Dynamics, Inc. June 2020 Nashville, TN --Systems Spray-Cooled has received an order from Steel Dynamics, Inc. for Spray-Cooled™ equipment at their new mill in Sinton, TX currently under construction. The 2021 project includes equipment for their (2) Electric Arc Furnaces. The Spray-Cooled™ equipment will cover 100% of SDI’s furnace

3010, 2019The Systems Group Named a Top Specialty Contractor

Arkansas Company #350 in 2019 ENR Top 600 Specialty Contractors Ranking El Dorado, Ark., October 2019 – The Systems Group (tsg.bz), a leading specialty contractor serving the industrial market with a focus on steel mills, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking report released by Engineering News-Record (ENR), a

1510, 2019Systems Spray-Cooled receives an order from Europe for a new Spray-Cooled™ EAF Roof and Elbow

October 2019, Nashville, TN --Industeel Belgium sa (“Industeel”) has placed an order for a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof and Elbow with Systems Spray-Cooled. The 2020 design-build project includes a new EAF Roof, Elbow, engineering, laser scans, and accompanying equipment that will replace its existing tubular equipment. The full scope, in conjunction with

204, 2018The Systems Group is Making a BIG Economic Impact in Southern Arkansas

The Systems Group is Making a BIG Economic Impact in Southern Arkansas April 3, 2018, El Dorado, Arkansas - The Systems Group (TSG) is making a BIG difference in their hometown, manufacturing Spray-Cooled™ furnace equipment used in the steel making industry, one that in turn drives our national economy. TSG started in El Dorado in

2407, 2017Ovako Hofors Puts Safety at the Forefront with the First Spray-Cooled™ EAF Roof in the Nordic Region

July 24, 2017, El Dorado, Arkansas – Swedish steel producer Ovako has awarded Systems Spray-Cooled the contract to modernize and increase safety on their Electric Arc Furnace (EAF) with the first Spray-Cooled™ roof in the Nordic region, located at their bar, billet, tube, and rings facility in Hofors, Sweden. After first being exposed to Spray-Cooled

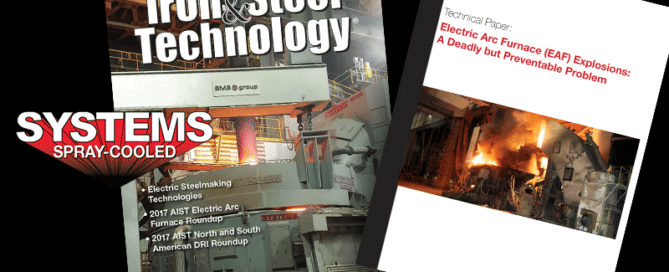

1301, 2017Systems Spray-Cooled News Flash: AIST Jan Front Cover, Safety First Article, & NYS Technical Article

Front Cover: Initial EAF Heat at Big River Steel of Osceola, AR Systems Spray-Cooled is proud to announce the appearance on the front page of the January 2017 AIST Iron & Steel Technology industry magazine. On the cover is Spray-Cooled's newest 165-ton furnace going into service at Big River Steel in Osceola, AR. Congratulations to

908, 2016The Systems Group Introduces Self-Maintaining Air Cleaner for Steel Mill Transformer Vaults, Motor Control Rooms and Other Critical Spaces

August 9, 2016, El Dorado, Arkansas -- The Systems Group (www.tsg.bz), a diverse group of companies engaged in construction, maintenance and products for steel manufacturing and other heavy industry, has introduced the first auto-cleaning air filtration system for steel mill transformer vaults, motor control rooms, air compressor systems, engine intakes and other critical spaces. The

1501, 2016Systems Spray-Cooled Makes AIST Front Cover

Systems Spray-Cooled™ Makes AIST Front Cover El Dorado, Ark., January 15, 2016 –Systems Spray-Cooled is proud to announce the appearance on the front page of the January 2016 AIST Iron & Steel Technology industry magazine. On the cover is a new single-bucket charge upper and lower electric arc furnace shells (6,500 ft3/184 m3) going into service at

2411, 2015The Systems Group Named a Top Specialty Contractor

Arkansas Company Advances to #268 in 2015 ENR Top 600 Specialty Contractors Ranking El Dorado, Ark., November 24, 2015 – The Systems Group (tsg.bz), a leading specialty contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking report released by Engineering News-Record

2010, 2015The Systems Group Donates Steel Structure for Engineering

“The Systems Group is honored to be part of helping the engineering students at Arkansas State,” Morgan explained. “The teaching sculpture allows teachers to show students the actual connections of structural beams used in commercial and industrial buildings and equipment structures. Systems is dedicated to helping create the next generation of people to help further the steel industry.”

1408, 2015The Systems Group Donates Quarter Million For Training Center Construction

El Dorado, AR, August 14, 2015: Representatives of The Systems Group and the Hays family donate $250,000 in honor of Charles A. Hays to help fund construction of the new South Arkansas Community College Advanced Manufacturing Training Center, which will break ground later this month. Hays, who founded The Systems Group more than 40 years

1407, 2015Updated Spray-Cooled™ Equipment Offers Enhanced Safety, Longevity, Uptime

El Dorado, AR, July 14, 2015: Systems Spray-Cooled™ (spraycooled.tsg.bz), which manufactures a line of non-pressurized, non-evaporative water-cooling equipment for the global metal and mineral industries, has updated its technology to incorporate several performance enhancements and new patented features that result in greater safety, equipment longevity and operational uptime.

2606, 2015Pagan Passes CWI Test

El Dorado, AR, June 26, 2015: Systems Fab & Machine in El Dorado, AR. proudly announces and congratulates one of their employees, Robert Pagan, for passing his CWI test in Memphis, TN. last week.

1506, 2015Summer Concert Series Downtown El Dorado AR

El Dorado, AR, June 15, 2015: Main Street El Dorado is proud to present the Murphy USA Summer Concert Series summer schedule. The concert series is free to the public and will feature national music artists performing outside on Union Square in the heart of historic downtown El Dorado. The concerts

1006, 2015Le Bonheur Charity Golf Tournament, Nucor Hickman

Hickman, AR, June 2015: The Systems Group participated recently in the Nucor Hickman charity golf tournament and auction benefitting the Le Bonheur Children’s hospital. It was June 7 & 8. Sunday evening June 7 was the auction and Systems donated $17,000 plus sponsoring a golf hole. Tony Lollar and Lee Morgan were there

3005, 2015Nucor Steel and Relay For Life Award

Decatur, Al, April 2015: Systems’ representative, Bud Christianson, accepts award from Nucor Steel’s Executive Vice President, Ladd Hall, recognizing the $10,000 donation by The Systems Group to the American Cancer Society’s Relay for Life in Decatur, AL.

2605, 2015The Systems Group Expands, Adds Fourth Division

El Dorado, Ark., May 26, 2015 – The Systems Group (TSG), (https://tsg.bz), a diverse group of companies engaged in construction, maintenance and products for steel manufacturing and other heavy industry, has just completed a corporate expansion which includes the addition of a new business unit and the re-naming of another.

912, 2014Lee Morgan Named President of The Systems Group

El Dorado, AR, December 9, 2014 – The Systems Group (TSG), (www.tsg.bz), a diverse group of companies engaged in fabrication, plant maintenance and construction for steel mills, foundries, metal processing plants, petrochemical plants and manufacturing facilities, announces that Lee Morgan has joined the company as its new president.

2011, 2014Systems Contracting Advances 10 Positions – ENR Top 600 Specialty Contractors

Systems Contracting advances 10 positions to #318 in the 2014 Engineering News-Record’s Top 600 Specialty Contractors. El Dorado, Ark., November 20, 2014 – Systems Contracting Corporation, a leading contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual

1302, 2014Systems Fab & Machine (American Steel Company) Completes CSA Certification

Acquires Canadian Welding Bureau (CWB) Certification Alongside its American Institute of Steel Construction (AISC) Certification El Dorado, AR, February 13, 2014: Systems Fab & Machine, formerly American Steel Company, a division of The Systems Group, announced it has received a letter of validation from the CWB (Canadian Welding Bureau) acknowledging that

402, 2014Systems Spray-Cooled / Nucor-Yamato Update

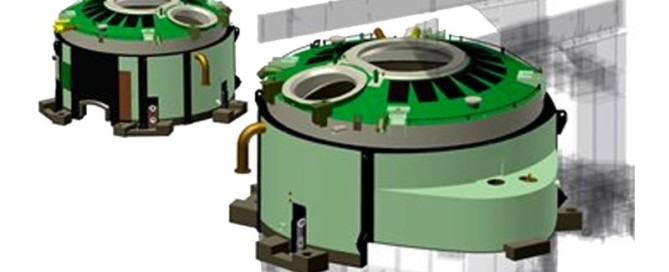

Project scheduled for on time delivery completion by the end of 2014 Nashville, TN, February 4, 2014: SYSTEMS Spray-Cooled, Inc. has completed the final design and engineering analysis of the new larger diameter Spray-Cooled™ roof, the new larger diameter and taller Spray-Cooled™ upper furnace shell along with a completely new design

101, 2014System Contracting Ranks in ENR’s Top 600 3 Years in a Row

System Contracting Corporation ranks #328 in the 2013 Engineering News Records. Systems continues to grow as a leading construction firm in the industrial, municipal and commercial construction markets. Our specialties include but are not limited to: Process Piping, Structural Concrete, Structural Steel Erection, Equipment Setting and Alignment, Plant Maintenance Services, Boiler

1411, 2013SYSTEMS Spray-Cooled Supplying New EAF Upper Shells and Roofs to Nucor-Yamato Steel

SYSTEMS Spray-Cooled, Inc. (SSCI) of Nashville, Tenn., has recently been awarded the contract to design and supply new larger and taller Spray-Cooled™ EAF upper shells and EAF roofs to Nucor-Yamato Steel for the company’s single bucket charge upgrade on its two existing EAFs in Blytheville, Ark.

101, 2013Systems Contracting Advances 36 Places

Systems Contracting Advances 36 Places in ENR’s List of Top Specialty Contractors The Systems Group continues to grow with its diverse group of privately held companies that are built on customer service with a firm belief that if it does not take care of its customers someone else will.

- 201, 2024

Systems Spray-Cooled receives order from Hybar

January 2024 Nashville, TN – Hybar, LLC has chosen Systems Spray-Cooled for the supply of Spray-Cooled™ EAF equipment at Hybar’s new rebar steelmaking facility located in Osceola, Arkansas. The new greenfield plant is being built on 1,300 acres in northeast Arkansas. The Spray-Cooled™ equipment will cover 100% of Hybar’s furnace cooling needs and will include

103, 2023Systems Spray-Cooled receives order from Nucor Steel West Virginia

March 2023 Nashville, TN –Nucor Steel Corporation has placed an order for new Electric Arc Furnace (EAF) equipment with Systems Spray-Cooled of The Systems Group for its greenfield sheet mill located in Mason County, WV. The Spray-Cooled™ equipment will cover 100% of Nucor Steel’s furnace cooling needs and will include the furnace sidewall, roof, and

112, 2022Systems Spray-Cooled™ receives order from Nucor Steel Lexington

December 2022 Nashville, TN –Nucor Steel Corporation has placed an order for new Electric Arc Furnace (EAF) equipment with Systems Spray-Cooled of The Systems Group for its recently announced micro-mill located in Lexington, NC. The Spray-Cooled ™ equipment will cover 100% of Nucor Steel’s furnace cooling needs and will include the furnace sidewall, roof, and elbow.

105, 2022Systems announces large expansion to El Dorado fabrication and machine shop, adding 60 new jobs

May 2022 El Dorado, AR – The Systems Group is pleased to announce a new expansion to their main fabrication and machine shop in El Dorado, AR. With the growth of Systems in all of their business units focused on the U.S. steel production industry, they will be purchasing 47 acres of land next to their

1002, 2022Systems installs and commissions new Spray-Cooled™ Electric Arc Furnace (EAF) equipment and a complete engineering package at EVRAZ Steel

February 2022 Nashville, TN – The SYSTEMS Group, received an order from EVRAZ North America, for the installation of Spray-Cooled™ equipment at its steelmaking facility located in Pueblo, Colorado. The 2022 turn key project includes new spray-cooled Electric Arc Furnace (EAF) equipment and a complete engineering package that covers a laser scan of the entire

102, 2022Systems installs and commissions new Spray-Cooled™ Gravity Drained EAF Roof at Optimus Steel

February 2022 Nashville, TN – As part of its mill modernization upgrade that was completed last month, Optimus Steel, Beaumont, TX installed and commissioned a new Spray-Cooled™ electric arc furnace (EAF) roof and elbow with Systems Spray-Cooled. The design-build-install project includes a new EAF roof, elbow, engineering, laser scans, and accompanying equipment that will replace

2311, 2021Ovako Hofors Puts Safety at the Forefront with the First Spray-Cooled™ EAF Roof in the Nordic Region

July 24, 2017, El Dorado, Arkansas – Swedish steel producer Ovako has awarded Systems Spray-Cooled the contract to modernize and increase safety on their Electric Arc Furnace (EAF) with the first Spray-Cooled™ roof in the Nordic region, located at their bar, billet, tube, and rings facility in Hofors, Sweden. After first being exposed to Spray-Cooled

808, 2021NEW SMAC MINI PULSE-CLEANED AIR CLEANER OFFERS HOSPITAL GRADE FILTRATION FOR CRANE CABS

The Systems Group (TSG) has introduced a new pulse-cleaned industrial air cleaner that efficiently filters the inside of crane cabs for operator safety and comfort. Called the SMAC Mini, it is a compact version of the company’s Self-Maintaining Air Cleaner (SMAC), their flagship heavy-duty air filtration system for steel mills and heavy industry.

2506, 2021Systems Spray-Cooled installs and commissions a new Spray-Cooled™ EAF Roof and Elbow at Industeel Belgium

ArcelorMittal Industeel Belgium (“Industeel”) has installed and successfully commissioned a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof and Elbow with Systems Spray-Cooled of The System Group.

205, 2021Systems Spray-Cooled Recently Completes BRS Phase II Melt Shop Expansion

As part of its Phase Two expansion that was recently completed, Big River Steel in Osceola, Arkansas installed and commissioned new Spray-Cooled™ on furnace electric arc furnace (EAF) equipment including a roof, elbow, sidewall and off-gas duct work with Systems Spray-Cooled from The Systems Group.

612, 2020Systems Spray-Cooled receives contract from Nucor Steel Brandenburg

Systems Spray-Cooled™, of The Systems Group, was selected to supply the electric arc furnace (EAF) Spray-Cooled™ equipment to Nucor Corporation’s new plate mill in Brandenburg, KY. The new EAF greenfield project includes equipment for a single EAF operation.

1911, 2020Systems Contracting Advances 9 Positions – ENR Top 600 Specialty Contractors

Systems Contracting advances 9 positions to #341 in the 2020 Engineering News-Record’s Top 600 Specialty Contractors. El Dorado, Ark., November 19, 2020 – Systems Contracting Corporation, a leading contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking

1509, 2020Systems Spray-Cooled Delivers Equipment to Nucor Steel Gallatin

Systems Spray-Cooled Delivers Equipment to Nucor Steel Gallatin September 2020 Nashville, TN --Nucor Steel is expanding the steelmaking capacity at its flat-rolled sheet steel mill located in Ghent, KY. As part of the expansion project, Nucor is adding a new 175-ton EAF that will increase the mill’s annual capacity from 1.6 million tons to approximately

107, 2020Systems Spray-Cooled receives an order to upgrade Optimus Steel EAF

Systems Spray-Cooled receives an order to upgrade Optimus Steel EAF July 2020 Nashville, TN -- Optimus Steel has placed an order for a furnace upgrade solution with Systems Spray-Cooled of The Systems Group. The 4th quarter 2020 turn-key project includes a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof, a new Spray-Cooled™ Elbow, the accompanying equipment that will replace

106, 2020Systems Spray-Cooled receives order from Steel Dynamics, Inc.

Systems Spray-Cooled receives order from Steel Dynamics, Inc. June 2020 Nashville, TN --Systems Spray-Cooled has received an order from Steel Dynamics, Inc. for Spray-Cooled™ equipment at their new mill in Sinton, TX currently under construction. The 2021 project includes equipment for their (2) Electric Arc Furnaces. The Spray-Cooled™ equipment will cover 100% of SDI’s furnace

3010, 2019The Systems Group Named a Top Specialty Contractor

Arkansas Company #350 in 2019 ENR Top 600 Specialty Contractors Ranking El Dorado, Ark., October 2019 – The Systems Group (tsg.bz), a leading specialty contractor serving the industrial market with a focus on steel mills, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking report released by Engineering News-Record (ENR), a

1510, 2019Systems Spray-Cooled receives an order from Europe for a new Spray-Cooled™ EAF Roof and Elbow

October 2019, Nashville, TN --Industeel Belgium sa (“Industeel”) has placed an order for a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof and Elbow with Systems Spray-Cooled. The 2020 design-build project includes a new EAF Roof, Elbow, engineering, laser scans, and accompanying equipment that will replace its existing tubular equipment. The full scope, in conjunction with

204, 2018The Systems Group is Making a BIG Economic Impact in Southern Arkansas

The Systems Group is Making a BIG Economic Impact in Southern Arkansas April 3, 2018, El Dorado, Arkansas - The Systems Group (TSG) is making a BIG difference in their hometown, manufacturing Spray-Cooled™ furnace equipment used in the steel making industry, one that in turn drives our national economy. TSG started in El Dorado in

2407, 2017Ovako Hofors Puts Safety at the Forefront with the First Spray-Cooled™ EAF Roof in the Nordic Region

July 24, 2017, El Dorado, Arkansas – Swedish steel producer Ovako has awarded Systems Spray-Cooled the contract to modernize and increase safety on their Electric Arc Furnace (EAF) with the first Spray-Cooled™ roof in the Nordic region, located at their bar, billet, tube, and rings facility in Hofors, Sweden. After first being exposed to Spray-Cooled

1301, 2017Systems Spray-Cooled News Flash: AIST Jan Front Cover, Safety First Article, & NYS Technical Article

Front Cover: Initial EAF Heat at Big River Steel of Osceola, AR Systems Spray-Cooled is proud to announce the appearance on the front page of the January 2017 AIST Iron & Steel Technology industry magazine. On the cover is Spray-Cooled's newest 165-ton furnace going into service at Big River Steel in Osceola, AR. Congratulations to

908, 2016The Systems Group Introduces Self-Maintaining Air Cleaner for Steel Mill Transformer Vaults, Motor Control Rooms and Other Critical Spaces

August 9, 2016, El Dorado, Arkansas -- The Systems Group (www.tsg.bz), a diverse group of companies engaged in construction, maintenance and products for steel manufacturing and other heavy industry, has introduced the first auto-cleaning air filtration system for steel mill transformer vaults, motor control rooms, air compressor systems, engine intakes and other critical spaces. The

1501, 2016Systems Spray-Cooled Makes AIST Front Cover

Systems Spray-Cooled™ Makes AIST Front Cover El Dorado, Ark., January 15, 2016 –Systems Spray-Cooled is proud to announce the appearance on the front page of the January 2016 AIST Iron & Steel Technology industry magazine. On the cover is a new single-bucket charge upper and lower electric arc furnace shells (6,500 ft3/184 m3) going into service at

2411, 2015The Systems Group Named a Top Specialty Contractor

Arkansas Company Advances to #268 in 2015 ENR Top 600 Specialty Contractors Ranking El Dorado, Ark., November 24, 2015 – The Systems Group (tsg.bz), a leading specialty contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking report released by Engineering News-Record

2010, 2015The Systems Group Donates Steel Structure for Engineering

“The Systems Group is honored to be part of helping the engineering students at Arkansas State,” Morgan explained. “The teaching sculpture allows teachers to show students the actual connections of structural beams used in commercial and industrial buildings and equipment structures. Systems is dedicated to helping create the next generation of people to help further the steel industry.”

1408, 2015The Systems Group Donates Quarter Million For Training Center Construction

El Dorado, AR, August 14, 2015: Representatives of The Systems Group and the Hays family donate $250,000 in honor of Charles A. Hays to help fund construction of the new South Arkansas Community College Advanced Manufacturing Training Center, which will break ground later this month. Hays, who founded The Systems Group more than 40 years

1407, 2015Updated Spray-Cooled™ Equipment Offers Enhanced Safety, Longevity, Uptime

El Dorado, AR, July 14, 2015: Systems Spray-Cooled™ (spraycooled.tsg.bz), which manufactures a line of non-pressurized, non-evaporative water-cooling equipment for the global metal and mineral industries, has updated its technology to incorporate several performance enhancements and new patented features that result in greater safety, equipment longevity and operational uptime.

2606, 2015Pagan Passes CWI Test

El Dorado, AR, June 26, 2015: Systems Fab & Machine in El Dorado, AR. proudly announces and congratulates one of their employees, Robert Pagan, for passing his CWI test in Memphis, TN. last week.

1506, 2015Summer Concert Series Downtown El Dorado AR

El Dorado, AR, June 15, 2015: Main Street El Dorado is proud to present the Murphy USA Summer Concert Series summer schedule. The concert series is free to the public and will feature national music artists performing outside on Union Square in the heart of historic downtown El Dorado. The concerts

1006, 2015Le Bonheur Charity Golf Tournament, Nucor Hickman

Hickman, AR, June 2015: The Systems Group participated recently in the Nucor Hickman charity golf tournament and auction benefitting the Le Bonheur Children’s hospital. It was June 7 & 8. Sunday evening June 7 was the auction and Systems donated $17,000 plus sponsoring a golf hole. Tony Lollar and Lee Morgan were there

3005, 2015Nucor Steel and Relay For Life Award

Decatur, Al, April 2015: Systems’ representative, Bud Christianson, accepts award from Nucor Steel’s Executive Vice President, Ladd Hall, recognizing the $10,000 donation by The Systems Group to the American Cancer Society’s Relay for Life in Decatur, AL.

2605, 2015The Systems Group Expands, Adds Fourth Division

El Dorado, Ark., May 26, 2015 – The Systems Group (TSG), (https://tsg.bz), a diverse group of companies engaged in construction, maintenance and products for steel manufacturing and other heavy industry, has just completed a corporate expansion which includes the addition of a new business unit and the re-naming of another.

912, 2014Lee Morgan Named President of The Systems Group

El Dorado, AR, December 9, 2014 – The Systems Group (TSG), (www.tsg.bz), a diverse group of companies engaged in fabrication, plant maintenance and construction for steel mills, foundries, metal processing plants, petrochemical plants and manufacturing facilities, announces that Lee Morgan has joined the company as its new president.

2011, 2014Systems Contracting Advances 10 Positions – ENR Top 600 Specialty Contractors

Systems Contracting advances 10 positions to #318 in the 2014 Engineering News-Record’s Top 600 Specialty Contractors. El Dorado, Ark., November 20, 2014 – Systems Contracting Corporation, a leading contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual

1302, 2014Systems Fab & Machine (American Steel Company) Completes CSA Certification

Acquires Canadian Welding Bureau (CWB) Certification Alongside its American Institute of Steel Construction (AISC) Certification El Dorado, AR, February 13, 2014: Systems Fab & Machine, formerly American Steel Company, a division of The Systems Group, announced it has received a letter of validation from the CWB (Canadian Welding Bureau) acknowledging that

402, 2014Systems Spray-Cooled / Nucor-Yamato Update

Project scheduled for on time delivery completion by the end of 2014 Nashville, TN, February 4, 2014: SYSTEMS Spray-Cooled, Inc. has completed the final design and engineering analysis of the new larger diameter Spray-Cooled™ roof, the new larger diameter and taller Spray-Cooled™ upper furnace shell along with a completely new design

101, 2014System Contracting Ranks in ENR’s Top 600 3 Years in a Row

System Contracting Corporation ranks #328 in the 2013 Engineering News Records. Systems continues to grow as a leading construction firm in the industrial, municipal and commercial construction markets. Our specialties include but are not limited to: Process Piping, Structural Concrete, Structural Steel Erection, Equipment Setting and Alignment, Plant Maintenance Services, Boiler

1411, 2013SYSTEMS Spray-Cooled Supplying New EAF Upper Shells and Roofs to Nucor-Yamato Steel

SYSTEMS Spray-Cooled, Inc. (SSCI) of Nashville, Tenn., has recently been awarded the contract to design and supply new larger and taller Spray-Cooled™ EAF upper shells and EAF roofs to Nucor-Yamato Steel for the company’s single bucket charge upgrade on its two existing EAFs in Blytheville, Ark.

101, 2013Systems Contracting Advances 36 Places

Systems Contracting Advances 36 Places in ENR’s List of Top Specialty Contractors The Systems Group continues to grow with its diverse group of privately held companies that are built on customer service with a firm belief that if it does not take care of its customers someone else will.

- 201, 2024

Systems Spray-Cooled receives order from Hybar

January 2024 Nashville, TN – Hybar, LLC has chosen Systems Spray-Cooled for the supply of Spray-Cooled™ EAF equipment at Hybar’s new rebar steelmaking facility located in Osceola, Arkansas. The new greenfield plant is being built on 1,300 acres in northeast Arkansas. The Spray-Cooled™ equipment will cover 100% of Hybar’s furnace cooling needs and will include

103, 2023Systems Spray-Cooled receives order from Nucor Steel West Virginia

March 2023 Nashville, TN –Nucor Steel Corporation has placed an order for new Electric Arc Furnace (EAF) equipment with Systems Spray-Cooled of The Systems Group for its greenfield sheet mill located in Mason County, WV. The Spray-Cooled™ equipment will cover 100% of Nucor Steel’s furnace cooling needs and will include the furnace sidewall, roof, and

112, 2022Systems Spray-Cooled™ receives order from Nucor Steel Lexington

December 2022 Nashville, TN –Nucor Steel Corporation has placed an order for new Electric Arc Furnace (EAF) equipment with Systems Spray-Cooled of The Systems Group for its recently announced micro-mill located in Lexington, NC. The Spray-Cooled ™ equipment will cover 100% of Nucor Steel’s furnace cooling needs and will include the furnace sidewall, roof, and elbow.

105, 2022Systems announces large expansion to El Dorado fabrication and machine shop, adding 60 new jobs

May 2022 El Dorado, AR – The Systems Group is pleased to announce a new expansion to their main fabrication and machine shop in El Dorado, AR. With the growth of Systems in all of their business units focused on the U.S. steel production industry, they will be purchasing 47 acres of land next to their

1002, 2022Systems installs and commissions new Spray-Cooled™ Electric Arc Furnace (EAF) equipment and a complete engineering package at EVRAZ Steel

February 2022 Nashville, TN – The SYSTEMS Group, received an order from EVRAZ North America, for the installation of Spray-Cooled™ equipment at its steelmaking facility located in Pueblo, Colorado. The 2022 turn key project includes new spray-cooled Electric Arc Furnace (EAF) equipment and a complete engineering package that covers a laser scan of the entire

102, 2022Systems installs and commissions new Spray-Cooled™ Gravity Drained EAF Roof at Optimus Steel

February 2022 Nashville, TN – As part of its mill modernization upgrade that was completed last month, Optimus Steel, Beaumont, TX installed and commissioned a new Spray-Cooled™ electric arc furnace (EAF) roof and elbow with Systems Spray-Cooled. The design-build-install project includes a new EAF roof, elbow, engineering, laser scans, and accompanying equipment that will replace

2311, 2021Ovako Hofors Puts Safety at the Forefront with the First Spray-Cooled™ EAF Roof in the Nordic Region

July 24, 2017, El Dorado, Arkansas – Swedish steel producer Ovako has awarded Systems Spray-Cooled the contract to modernize and increase safety on their Electric Arc Furnace (EAF) with the first Spray-Cooled™ roof in the Nordic region, located at their bar, billet, tube, and rings facility in Hofors, Sweden. After first being exposed to Spray-Cooled

808, 2021NEW SMAC MINI PULSE-CLEANED AIR CLEANER OFFERS HOSPITAL GRADE FILTRATION FOR CRANE CABS

The Systems Group (TSG) has introduced a new pulse-cleaned industrial air cleaner that efficiently filters the inside of crane cabs for operator safety and comfort. Called the SMAC Mini, it is a compact version of the company’s Self-Maintaining Air Cleaner (SMAC), their flagship heavy-duty air filtration system for steel mills and heavy industry.

2506, 2021Systems Spray-Cooled installs and commissions a new Spray-Cooled™ EAF Roof and Elbow at Industeel Belgium

ArcelorMittal Industeel Belgium (“Industeel”) has installed and successfully commissioned a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof and Elbow with Systems Spray-Cooled of The System Group.

205, 2021Systems Spray-Cooled Recently Completes BRS Phase II Melt Shop Expansion

As part of its Phase Two expansion that was recently completed, Big River Steel in Osceola, Arkansas installed and commissioned new Spray-Cooled™ on furnace electric arc furnace (EAF) equipment including a roof, elbow, sidewall and off-gas duct work with Systems Spray-Cooled from The Systems Group.

612, 2020Systems Spray-Cooled receives contract from Nucor Steel Brandenburg

Systems Spray-Cooled™, of The Systems Group, was selected to supply the electric arc furnace (EAF) Spray-Cooled™ equipment to Nucor Corporation’s new plate mill in Brandenburg, KY. The new EAF greenfield project includes equipment for a single EAF operation.

1911, 2020Systems Contracting Advances 9 Positions – ENR Top 600 Specialty Contractors

Systems Contracting advances 9 positions to #341 in the 2020 Engineering News-Record’s Top 600 Specialty Contractors. El Dorado, Ark., November 19, 2020 – Systems Contracting Corporation, a leading contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking

1509, 2020Systems Spray-Cooled Delivers Equipment to Nucor Steel Gallatin

Systems Spray-Cooled Delivers Equipment to Nucor Steel Gallatin September 2020 Nashville, TN --Nucor Steel is expanding the steelmaking capacity at its flat-rolled sheet steel mill located in Ghent, KY. As part of the expansion project, Nucor is adding a new 175-ton EAF that will increase the mill’s annual capacity from 1.6 million tons to approximately

107, 2020Systems Spray-Cooled receives an order to upgrade Optimus Steel EAF

Systems Spray-Cooled receives an order to upgrade Optimus Steel EAF July 2020 Nashville, TN -- Optimus Steel has placed an order for a furnace upgrade solution with Systems Spray-Cooled of The Systems Group. The 4th quarter 2020 turn-key project includes a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof, a new Spray-Cooled™ Elbow, the accompanying equipment that will replace

106, 2020Systems Spray-Cooled receives order from Steel Dynamics, Inc.

Systems Spray-Cooled receives order from Steel Dynamics, Inc. June 2020 Nashville, TN --Systems Spray-Cooled has received an order from Steel Dynamics, Inc. for Spray-Cooled™ equipment at their new mill in Sinton, TX currently under construction. The 2021 project includes equipment for their (2) Electric Arc Furnaces. The Spray-Cooled™ equipment will cover 100% of SDI’s furnace

3010, 2019The Systems Group Named a Top Specialty Contractor

Arkansas Company #350 in 2019 ENR Top 600 Specialty Contractors Ranking El Dorado, Ark., October 2019 – The Systems Group (tsg.bz), a leading specialty contractor serving the industrial market with a focus on steel mills, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking report released by Engineering News-Record (ENR), a

1510, 2019Systems Spray-Cooled receives an order from Europe for a new Spray-Cooled™ EAF Roof and Elbow

October 2019, Nashville, TN --Industeel Belgium sa (“Industeel”) has placed an order for a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof and Elbow with Systems Spray-Cooled. The 2020 design-build project includes a new EAF Roof, Elbow, engineering, laser scans, and accompanying equipment that will replace its existing tubular equipment. The full scope, in conjunction with

204, 2018The Systems Group is Making a BIG Economic Impact in Southern Arkansas

The Systems Group is Making a BIG Economic Impact in Southern Arkansas April 3, 2018, El Dorado, Arkansas - The Systems Group (TSG) is making a BIG difference in their hometown, manufacturing Spray-Cooled™ furnace equipment used in the steel making industry, one that in turn drives our national economy. TSG started in El Dorado in

2407, 2017Ovako Hofors Puts Safety at the Forefront with the First Spray-Cooled™ EAF Roof in the Nordic Region

July 24, 2017, El Dorado, Arkansas – Swedish steel producer Ovako has awarded Systems Spray-Cooled the contract to modernize and increase safety on their Electric Arc Furnace (EAF) with the first Spray-Cooled™ roof in the Nordic region, located at their bar, billet, tube, and rings facility in Hofors, Sweden. After first being exposed to Spray-Cooled

1301, 2017Systems Spray-Cooled News Flash: AIST Jan Front Cover, Safety First Article, & NYS Technical Article

Front Cover: Initial EAF Heat at Big River Steel of Osceola, AR Systems Spray-Cooled is proud to announce the appearance on the front page of the January 2017 AIST Iron & Steel Technology industry magazine. On the cover is Spray-Cooled's newest 165-ton furnace going into service at Big River Steel in Osceola, AR. Congratulations to

908, 2016The Systems Group Introduces Self-Maintaining Air Cleaner for Steel Mill Transformer Vaults, Motor Control Rooms and Other Critical Spaces

August 9, 2016, El Dorado, Arkansas -- The Systems Group (www.tsg.bz), a diverse group of companies engaged in construction, maintenance and products for steel manufacturing and other heavy industry, has introduced the first auto-cleaning air filtration system for steel mill transformer vaults, motor control rooms, air compressor systems, engine intakes and other critical spaces. The

1501, 2016Systems Spray-Cooled Makes AIST Front Cover

Systems Spray-Cooled™ Makes AIST Front Cover El Dorado, Ark., January 15, 2016 –Systems Spray-Cooled is proud to announce the appearance on the front page of the January 2016 AIST Iron & Steel Technology industry magazine. On the cover is a new single-bucket charge upper and lower electric arc furnace shells (6,500 ft3/184 m3) going into service at

2411, 2015The Systems Group Named a Top Specialty Contractor

Arkansas Company Advances to #268 in 2015 ENR Top 600 Specialty Contractors Ranking El Dorado, Ark., November 24, 2015 – The Systems Group (tsg.bz), a leading specialty contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking report released by Engineering News-Record

2010, 2015The Systems Group Donates Steel Structure for Engineering

“The Systems Group is honored to be part of helping the engineering students at Arkansas State,” Morgan explained. “The teaching sculpture allows teachers to show students the actual connections of structural beams used in commercial and industrial buildings and equipment structures. Systems is dedicated to helping create the next generation of people to help further the steel industry.”

1408, 2015The Systems Group Donates Quarter Million For Training Center Construction

El Dorado, AR, August 14, 2015: Representatives of The Systems Group and the Hays family donate $250,000 in honor of Charles A. Hays to help fund construction of the new South Arkansas Community College Advanced Manufacturing Training Center, which will break ground later this month. Hays, who founded The Systems Group more than 40 years

1407, 2015Updated Spray-Cooled™ Equipment Offers Enhanced Safety, Longevity, Uptime

El Dorado, AR, July 14, 2015: Systems Spray-Cooled™ (spraycooled.tsg.bz), which manufactures a line of non-pressurized, non-evaporative water-cooling equipment for the global metal and mineral industries, has updated its technology to incorporate several performance enhancements and new patented features that result in greater safety, equipment longevity and operational uptime.

2606, 2015Pagan Passes CWI Test

El Dorado, AR, June 26, 2015: Systems Fab & Machine in El Dorado, AR. proudly announces and congratulates one of their employees, Robert Pagan, for passing his CWI test in Memphis, TN. last week.

1506, 2015Summer Concert Series Downtown El Dorado AR

El Dorado, AR, June 15, 2015: Main Street El Dorado is proud to present the Murphy USA Summer Concert Series summer schedule. The concert series is free to the public and will feature national music artists performing outside on Union Square in the heart of historic downtown El Dorado. The concerts

1006, 2015Le Bonheur Charity Golf Tournament, Nucor Hickman

Hickman, AR, June 2015: The Systems Group participated recently in the Nucor Hickman charity golf tournament and auction benefitting the Le Bonheur Children’s hospital. It was June 7 & 8. Sunday evening June 7 was the auction and Systems donated $17,000 plus sponsoring a golf hole. Tony Lollar and Lee Morgan were there

3005, 2015Nucor Steel and Relay For Life Award

Decatur, Al, April 2015: Systems’ representative, Bud Christianson, accepts award from Nucor Steel’s Executive Vice President, Ladd Hall, recognizing the $10,000 donation by The Systems Group to the American Cancer Society’s Relay for Life in Decatur, AL.

2605, 2015The Systems Group Expands, Adds Fourth Division

El Dorado, Ark., May 26, 2015 – The Systems Group (TSG), (https://tsg.bz), a diverse group of companies engaged in construction, maintenance and products for steel manufacturing and other heavy industry, has just completed a corporate expansion which includes the addition of a new business unit and the re-naming of another.

912, 2014Lee Morgan Named President of The Systems Group

El Dorado, AR, December 9, 2014 – The Systems Group (TSG), (www.tsg.bz), a diverse group of companies engaged in fabrication, plant maintenance and construction for steel mills, foundries, metal processing plants, petrochemical plants and manufacturing facilities, announces that Lee Morgan has joined the company as its new president.

2011, 2014Systems Contracting Advances 10 Positions – ENR Top 600 Specialty Contractors

Systems Contracting advances 10 positions to #318 in the 2014 Engineering News-Record’s Top 600 Specialty Contractors. El Dorado, Ark., November 20, 2014 – Systems Contracting Corporation, a leading contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual

1302, 2014Systems Fab & Machine (American Steel Company) Completes CSA Certification

Acquires Canadian Welding Bureau (CWB) Certification Alongside its American Institute of Steel Construction (AISC) Certification El Dorado, AR, February 13, 2014: Systems Fab & Machine, formerly American Steel Company, a division of The Systems Group, announced it has received a letter of validation from the CWB (Canadian Welding Bureau) acknowledging that

402, 2014Systems Spray-Cooled / Nucor-Yamato Update

Project scheduled for on time delivery completion by the end of 2014 Nashville, TN, February 4, 2014: SYSTEMS Spray-Cooled, Inc. has completed the final design and engineering analysis of the new larger diameter Spray-Cooled™ roof, the new larger diameter and taller Spray-Cooled™ upper furnace shell along with a completely new design

101, 2014System Contracting Ranks in ENR’s Top 600 3 Years in a Row

System Contracting Corporation ranks #328 in the 2013 Engineering News Records. Systems continues to grow as a leading construction firm in the industrial, municipal and commercial construction markets. Our specialties include but are not limited to: Process Piping, Structural Concrete, Structural Steel Erection, Equipment Setting and Alignment, Plant Maintenance Services, Boiler

1411, 2013SYSTEMS Spray-Cooled Supplying New EAF Upper Shells and Roofs to Nucor-Yamato Steel

SYSTEMS Spray-Cooled, Inc. (SSCI) of Nashville, Tenn., has recently been awarded the contract to design and supply new larger and taller Spray-Cooled™ EAF upper shells and EAF roofs to Nucor-Yamato Steel for the company’s single bucket charge upgrade on its two existing EAFs in Blytheville, Ark.

101, 2013Systems Contracting Advances 36 Places

Systems Contracting Advances 36 Places in ENR’s List of Top Specialty Contractors The Systems Group continues to grow with its diverse group of privately held companies that are built on customer service with a firm belief that if it does not take care of its customers someone else will.

- 201, 2024

Systems Spray-Cooled receives order from Hybar

January 2024 Nashville, TN – Hybar, LLC has chosen Systems Spray-Cooled for the supply of Spray-Cooled™ EAF equipment at Hybar’s new rebar steelmaking facility located in Osceola, Arkansas. The new greenfield plant is being built on 1,300 acres in northeast Arkansas. The Spray-Cooled™ equipment will cover 100% of Hybar’s furnace cooling needs and will include

103, 2023Systems Spray-Cooled receives order from Nucor Steel West Virginia

March 2023 Nashville, TN –Nucor Steel Corporation has placed an order for new Electric Arc Furnace (EAF) equipment with Systems Spray-Cooled of The Systems Group for its greenfield sheet mill located in Mason County, WV. The Spray-Cooled™ equipment will cover 100% of Nucor Steel’s furnace cooling needs and will include the furnace sidewall, roof, and

112, 2022Systems Spray-Cooled™ receives order from Nucor Steel Lexington

December 2022 Nashville, TN –Nucor Steel Corporation has placed an order for new Electric Arc Furnace (EAF) equipment with Systems Spray-Cooled of The Systems Group for its recently announced micro-mill located in Lexington, NC. The Spray-Cooled ™ equipment will cover 100% of Nucor Steel’s furnace cooling needs and will include the furnace sidewall, roof, and elbow.

105, 2022Systems announces large expansion to El Dorado fabrication and machine shop, adding 60 new jobs

May 2022 El Dorado, AR – The Systems Group is pleased to announce a new expansion to their main fabrication and machine shop in El Dorado, AR. With the growth of Systems in all of their business units focused on the U.S. steel production industry, they will be purchasing 47 acres of land next to their

1002, 2022Systems installs and commissions new Spray-Cooled™ Electric Arc Furnace (EAF) equipment and a complete engineering package at EVRAZ Steel

February 2022 Nashville, TN – The SYSTEMS Group, received an order from EVRAZ North America, for the installation of Spray-Cooled™ equipment at its steelmaking facility located in Pueblo, Colorado. The 2022 turn key project includes new spray-cooled Electric Arc Furnace (EAF) equipment and a complete engineering package that covers a laser scan of the entire

102, 2022Systems installs and commissions new Spray-Cooled™ Gravity Drained EAF Roof at Optimus Steel

February 2022 Nashville, TN – As part of its mill modernization upgrade that was completed last month, Optimus Steel, Beaumont, TX installed and commissioned a new Spray-Cooled™ electric arc furnace (EAF) roof and elbow with Systems Spray-Cooled. The design-build-install project includes a new EAF roof, elbow, engineering, laser scans, and accompanying equipment that will replace

2311, 2021Ovako Hofors Puts Safety at the Forefront with the First Spray-Cooled™ EAF Roof in the Nordic Region

July 24, 2017, El Dorado, Arkansas – Swedish steel producer Ovako has awarded Systems Spray-Cooled the contract to modernize and increase safety on their Electric Arc Furnace (EAF) with the first Spray-Cooled™ roof in the Nordic region, located at their bar, billet, tube, and rings facility in Hofors, Sweden. After first being exposed to Spray-Cooled

808, 2021NEW SMAC MINI PULSE-CLEANED AIR CLEANER OFFERS HOSPITAL GRADE FILTRATION FOR CRANE CABS

The Systems Group (TSG) has introduced a new pulse-cleaned industrial air cleaner that efficiently filters the inside of crane cabs for operator safety and comfort. Called the SMAC Mini, it is a compact version of the company’s Self-Maintaining Air Cleaner (SMAC), their flagship heavy-duty air filtration system for steel mills and heavy industry.

2506, 2021Systems Spray-Cooled installs and commissions a new Spray-Cooled™ EAF Roof and Elbow at Industeel Belgium

ArcelorMittal Industeel Belgium (“Industeel”) has installed and successfully commissioned a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof and Elbow with Systems Spray-Cooled of The System Group.

205, 2021Systems Spray-Cooled Recently Completes BRS Phase II Melt Shop Expansion

As part of its Phase Two expansion that was recently completed, Big River Steel in Osceola, Arkansas installed and commissioned new Spray-Cooled™ on furnace electric arc furnace (EAF) equipment including a roof, elbow, sidewall and off-gas duct work with Systems Spray-Cooled from The Systems Group.

612, 2020Systems Spray-Cooled receives contract from Nucor Steel Brandenburg

Systems Spray-Cooled™, of The Systems Group, was selected to supply the electric arc furnace (EAF) Spray-Cooled™ equipment to Nucor Corporation’s new plate mill in Brandenburg, KY. The new EAF greenfield project includes equipment for a single EAF operation.

1911, 2020Systems Contracting Advances 9 Positions – ENR Top 600 Specialty Contractors

Systems Contracting advances 9 positions to #341 in the 2020 Engineering News-Record’s Top 600 Specialty Contractors. El Dorado, Ark., November 19, 2020 – Systems Contracting Corporation, a leading contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking

1509, 2020Systems Spray-Cooled Delivers Equipment to Nucor Steel Gallatin

Systems Spray-Cooled Delivers Equipment to Nucor Steel Gallatin September 2020 Nashville, TN --Nucor Steel is expanding the steelmaking capacity at its flat-rolled sheet steel mill located in Ghent, KY. As part of the expansion project, Nucor is adding a new 175-ton EAF that will increase the mill’s annual capacity from 1.6 million tons to approximately

107, 2020Systems Spray-Cooled receives an order to upgrade Optimus Steel EAF

Systems Spray-Cooled receives an order to upgrade Optimus Steel EAF July 2020 Nashville, TN -- Optimus Steel has placed an order for a furnace upgrade solution with Systems Spray-Cooled of The Systems Group. The 4th quarter 2020 turn-key project includes a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof, a new Spray-Cooled™ Elbow, the accompanying equipment that will replace

106, 2020Systems Spray-Cooled receives order from Steel Dynamics, Inc.

Systems Spray-Cooled receives order from Steel Dynamics, Inc. June 2020 Nashville, TN --Systems Spray-Cooled has received an order from Steel Dynamics, Inc. for Spray-Cooled™ equipment at their new mill in Sinton, TX currently under construction. The 2021 project includes equipment for their (2) Electric Arc Furnaces. The Spray-Cooled™ equipment will cover 100% of SDI’s furnace

3010, 2019The Systems Group Named a Top Specialty Contractor

Arkansas Company #350 in 2019 ENR Top 600 Specialty Contractors Ranking El Dorado, Ark., October 2019 – The Systems Group (tsg.bz), a leading specialty contractor serving the industrial market with a focus on steel mills, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking report released by Engineering News-Record (ENR), a

1510, 2019Systems Spray-Cooled receives an order from Europe for a new Spray-Cooled™ EAF Roof and Elbow

October 2019, Nashville, TN --Industeel Belgium sa (“Industeel”) has placed an order for a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof and Elbow with Systems Spray-Cooled. The 2020 design-build project includes a new EAF Roof, Elbow, engineering, laser scans, and accompanying equipment that will replace its existing tubular equipment. The full scope, in conjunction with

204, 2018The Systems Group is Making a BIG Economic Impact in Southern Arkansas

The Systems Group is Making a BIG Economic Impact in Southern Arkansas April 3, 2018, El Dorado, Arkansas - The Systems Group (TSG) is making a BIG difference in their hometown, manufacturing Spray-Cooled™ furnace equipment used in the steel making industry, one that in turn drives our national economy. TSG started in El Dorado in

2407, 2017Ovako Hofors Puts Safety at the Forefront with the First Spray-Cooled™ EAF Roof in the Nordic Region

July 24, 2017, El Dorado, Arkansas – Swedish steel producer Ovako has awarded Systems Spray-Cooled the contract to modernize and increase safety on their Electric Arc Furnace (EAF) with the first Spray-Cooled™ roof in the Nordic region, located at their bar, billet, tube, and rings facility in Hofors, Sweden. After first being exposed to Spray-Cooled

1301, 2017Systems Spray-Cooled News Flash: AIST Jan Front Cover, Safety First Article, & NYS Technical Article

Front Cover: Initial EAF Heat at Big River Steel of Osceola, AR Systems Spray-Cooled is proud to announce the appearance on the front page of the January 2017 AIST Iron & Steel Technology industry magazine. On the cover is Spray-Cooled's newest 165-ton furnace going into service at Big River Steel in Osceola, AR. Congratulations to

908, 2016The Systems Group Introduces Self-Maintaining Air Cleaner for Steel Mill Transformer Vaults, Motor Control Rooms and Other Critical Spaces

August 9, 2016, El Dorado, Arkansas -- The Systems Group (www.tsg.bz), a diverse group of companies engaged in construction, maintenance and products for steel manufacturing and other heavy industry, has introduced the first auto-cleaning air filtration system for steel mill transformer vaults, motor control rooms, air compressor systems, engine intakes and other critical spaces. The

1501, 2016Systems Spray-Cooled Makes AIST Front Cover

Systems Spray-Cooled™ Makes AIST Front Cover El Dorado, Ark., January 15, 2016 –Systems Spray-Cooled is proud to announce the appearance on the front page of the January 2016 AIST Iron & Steel Technology industry magazine. On the cover is a new single-bucket charge upper and lower electric arc furnace shells (6,500 ft3/184 m3) going into service at

2411, 2015The Systems Group Named a Top Specialty Contractor

Arkansas Company Advances to #268 in 2015 ENR Top 600 Specialty Contractors Ranking El Dorado, Ark., November 24, 2015 – The Systems Group (tsg.bz), a leading specialty contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking report released by Engineering News-Record

2010, 2015The Systems Group Donates Steel Structure for Engineering

“The Systems Group is honored to be part of helping the engineering students at Arkansas State,” Morgan explained. “The teaching sculpture allows teachers to show students the actual connections of structural beams used in commercial and industrial buildings and equipment structures. Systems is dedicated to helping create the next generation of people to help further the steel industry.”

1408, 2015The Systems Group Donates Quarter Million For Training Center Construction

El Dorado, AR, August 14, 2015: Representatives of The Systems Group and the Hays family donate $250,000 in honor of Charles A. Hays to help fund construction of the new South Arkansas Community College Advanced Manufacturing Training Center, which will break ground later this month. Hays, who founded The Systems Group more than 40 years

1407, 2015Updated Spray-Cooled™ Equipment Offers Enhanced Safety, Longevity, Uptime

El Dorado, AR, July 14, 2015: Systems Spray-Cooled™ (spraycooled.tsg.bz), which manufactures a line of non-pressurized, non-evaporative water-cooling equipment for the global metal and mineral industries, has updated its technology to incorporate several performance enhancements and new patented features that result in greater safety, equipment longevity and operational uptime.

2606, 2015Pagan Passes CWI Test

El Dorado, AR, June 26, 2015: Systems Fab & Machine in El Dorado, AR. proudly announces and congratulates one of their employees, Robert Pagan, for passing his CWI test in Memphis, TN. last week.

1506, 2015Summer Concert Series Downtown El Dorado AR

El Dorado, AR, June 15, 2015: Main Street El Dorado is proud to present the Murphy USA Summer Concert Series summer schedule. The concert series is free to the public and will feature national music artists performing outside on Union Square in the heart of historic downtown El Dorado. The concerts

1006, 2015Le Bonheur Charity Golf Tournament, Nucor Hickman

Hickman, AR, June 2015: The Systems Group participated recently in the Nucor Hickman charity golf tournament and auction benefitting the Le Bonheur Children’s hospital. It was June 7 & 8. Sunday evening June 7 was the auction and Systems donated $17,000 plus sponsoring a golf hole. Tony Lollar and Lee Morgan were there

3005, 2015Nucor Steel and Relay For Life Award

Decatur, Al, April 2015: Systems’ representative, Bud Christianson, accepts award from Nucor Steel’s Executive Vice President, Ladd Hall, recognizing the $10,000 donation by The Systems Group to the American Cancer Society’s Relay for Life in Decatur, AL.

2605, 2015The Systems Group Expands, Adds Fourth Division

El Dorado, Ark., May 26, 2015 – The Systems Group (TSG), (https://tsg.bz), a diverse group of companies engaged in construction, maintenance and products for steel manufacturing and other heavy industry, has just completed a corporate expansion which includes the addition of a new business unit and the re-naming of another.

912, 2014Lee Morgan Named President of The Systems Group

El Dorado, AR, December 9, 2014 – The Systems Group (TSG), (www.tsg.bz), a diverse group of companies engaged in fabrication, plant maintenance and construction for steel mills, foundries, metal processing plants, petrochemical plants and manufacturing facilities, announces that Lee Morgan has joined the company as its new president.

2011, 2014Systems Contracting Advances 10 Positions – ENR Top 600 Specialty Contractors

Systems Contracting advances 10 positions to #318 in the 2014 Engineering News-Record’s Top 600 Specialty Contractors. El Dorado, Ark., November 20, 2014 – Systems Contracting Corporation, a leading contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual

1302, 2014Systems Fab & Machine (American Steel Company) Completes CSA Certification

Acquires Canadian Welding Bureau (CWB) Certification Alongside its American Institute of Steel Construction (AISC) Certification El Dorado, AR, February 13, 2014: Systems Fab & Machine, formerly American Steel Company, a division of The Systems Group, announced it has received a letter of validation from the CWB (Canadian Welding Bureau) acknowledging that

402, 2014Systems Spray-Cooled / Nucor-Yamato Update

Project scheduled for on time delivery completion by the end of 2014 Nashville, TN, February 4, 2014: SYSTEMS Spray-Cooled, Inc. has completed the final design and engineering analysis of the new larger diameter Spray-Cooled™ roof, the new larger diameter and taller Spray-Cooled™ upper furnace shell along with a completely new design

101, 2014System Contracting Ranks in ENR’s Top 600 3 Years in a Row

System Contracting Corporation ranks #328 in the 2013 Engineering News Records. Systems continues to grow as a leading construction firm in the industrial, municipal and commercial construction markets. Our specialties include but are not limited to: Process Piping, Structural Concrete, Structural Steel Erection, Equipment Setting and Alignment, Plant Maintenance Services, Boiler

1411, 2013SYSTEMS Spray-Cooled Supplying New EAF Upper Shells and Roofs to Nucor-Yamato Steel

SYSTEMS Spray-Cooled, Inc. (SSCI) of Nashville, Tenn., has recently been awarded the contract to design and supply new larger and taller Spray-Cooled™ EAF upper shells and EAF roofs to Nucor-Yamato Steel for the company’s single bucket charge upgrade on its two existing EAFs in Blytheville, Ark.

101, 2013Systems Contracting Advances 36 Places

Systems Contracting Advances 36 Places in ENR’s List of Top Specialty Contractors The Systems Group continues to grow with its diverse group of privately held companies that are built on customer service with a firm belief that if it does not take care of its customers someone else will.

- 201, 2024

Systems Spray-Cooled receives order from Hybar

January 2024 Nashville, TN – Hybar, LLC has chosen Systems Spray-Cooled for the supply of Spray-Cooled™ EAF equipment at Hybar’s new rebar steelmaking facility located in Osceola, Arkansas. The new greenfield plant is being built on 1,300 acres in northeast Arkansas. The Spray-Cooled™ equipment will cover 100% of Hybar’s furnace cooling needs and will include

103, 2023Systems Spray-Cooled receives order from Nucor Steel West Virginia

March 2023 Nashville, TN –Nucor Steel Corporation has placed an order for new Electric Arc Furnace (EAF) equipment with Systems Spray-Cooled of The Systems Group for its greenfield sheet mill located in Mason County, WV. The Spray-Cooled™ equipment will cover 100% of Nucor Steel’s furnace cooling needs and will include the furnace sidewall, roof, and

112, 2022Systems Spray-Cooled™ receives order from Nucor Steel Lexington

December 2022 Nashville, TN –Nucor Steel Corporation has placed an order for new Electric Arc Furnace (EAF) equipment with Systems Spray-Cooled of The Systems Group for its recently announced micro-mill located in Lexington, NC. The Spray-Cooled ™ equipment will cover 100% of Nucor Steel’s furnace cooling needs and will include the furnace sidewall, roof, and elbow.

105, 2022Systems announces large expansion to El Dorado fabrication and machine shop, adding 60 new jobs

May 2022 El Dorado, AR – The Systems Group is pleased to announce a new expansion to their main fabrication and machine shop in El Dorado, AR. With the growth of Systems in all of their business units focused on the U.S. steel production industry, they will be purchasing 47 acres of land next to their

1002, 2022Systems installs and commissions new Spray-Cooled™ Electric Arc Furnace (EAF) equipment and a complete engineering package at EVRAZ Steel

February 2022 Nashville, TN – The SYSTEMS Group, received an order from EVRAZ North America, for the installation of Spray-Cooled™ equipment at its steelmaking facility located in Pueblo, Colorado. The 2022 turn key project includes new spray-cooled Electric Arc Furnace (EAF) equipment and a complete engineering package that covers a laser scan of the entire

102, 2022Systems installs and commissions new Spray-Cooled™ Gravity Drained EAF Roof at Optimus Steel

February 2022 Nashville, TN – As part of its mill modernization upgrade that was completed last month, Optimus Steel, Beaumont, TX installed and commissioned a new Spray-Cooled™ electric arc furnace (EAF) roof and elbow with Systems Spray-Cooled. The design-build-install project includes a new EAF roof, elbow, engineering, laser scans, and accompanying equipment that will replace

2311, 2021Ovako Hofors Puts Safety at the Forefront with the First Spray-Cooled™ EAF Roof in the Nordic Region

July 24, 2017, El Dorado, Arkansas – Swedish steel producer Ovako has awarded Systems Spray-Cooled the contract to modernize and increase safety on their Electric Arc Furnace (EAF) with the first Spray-Cooled™ roof in the Nordic region, located at their bar, billet, tube, and rings facility in Hofors, Sweden. After first being exposed to Spray-Cooled

808, 2021NEW SMAC MINI PULSE-CLEANED AIR CLEANER OFFERS HOSPITAL GRADE FILTRATION FOR CRANE CABS

The Systems Group (TSG) has introduced a new pulse-cleaned industrial air cleaner that efficiently filters the inside of crane cabs for operator safety and comfort. Called the SMAC Mini, it is a compact version of the company’s Self-Maintaining Air Cleaner (SMAC), their flagship heavy-duty air filtration system for steel mills and heavy industry.

2506, 2021Systems Spray-Cooled installs and commissions a new Spray-Cooled™ EAF Roof and Elbow at Industeel Belgium

ArcelorMittal Industeel Belgium (“Industeel”) has installed and successfully commissioned a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof and Elbow with Systems Spray-Cooled of The System Group.

205, 2021Systems Spray-Cooled Recently Completes BRS Phase II Melt Shop Expansion

As part of its Phase Two expansion that was recently completed, Big River Steel in Osceola, Arkansas installed and commissioned new Spray-Cooled™ on furnace electric arc furnace (EAF) equipment including a roof, elbow, sidewall and off-gas duct work with Systems Spray-Cooled from The Systems Group.

612, 2020Systems Spray-Cooled receives contract from Nucor Steel Brandenburg

Systems Spray-Cooled™, of The Systems Group, was selected to supply the electric arc furnace (EAF) Spray-Cooled™ equipment to Nucor Corporation’s new plate mill in Brandenburg, KY. The new EAF greenfield project includes equipment for a single EAF operation.

1911, 2020Systems Contracting Advances 9 Positions – ENR Top 600 Specialty Contractors

Systems Contracting advances 9 positions to #341 in the 2020 Engineering News-Record’s Top 600 Specialty Contractors. El Dorado, Ark., November 19, 2020 – Systems Contracting Corporation, a leading contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking

1509, 2020Systems Spray-Cooled Delivers Equipment to Nucor Steel Gallatin

Systems Spray-Cooled Delivers Equipment to Nucor Steel Gallatin September 2020 Nashville, TN --Nucor Steel is expanding the steelmaking capacity at its flat-rolled sheet steel mill located in Ghent, KY. As part of the expansion project, Nucor is adding a new 175-ton EAF that will increase the mill’s annual capacity from 1.6 million tons to approximately

107, 2020Systems Spray-Cooled receives an order to upgrade Optimus Steel EAF

Systems Spray-Cooled receives an order to upgrade Optimus Steel EAF July 2020 Nashville, TN -- Optimus Steel has placed an order for a furnace upgrade solution with Systems Spray-Cooled of The Systems Group. The 4th quarter 2020 turn-key project includes a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof, a new Spray-Cooled™ Elbow, the accompanying equipment that will replace

106, 2020Systems Spray-Cooled receives order from Steel Dynamics, Inc.

Systems Spray-Cooled receives order from Steel Dynamics, Inc. June 2020 Nashville, TN --Systems Spray-Cooled has received an order from Steel Dynamics, Inc. for Spray-Cooled™ equipment at their new mill in Sinton, TX currently under construction. The 2021 project includes equipment for their (2) Electric Arc Furnaces. The Spray-Cooled™ equipment will cover 100% of SDI’s furnace

3010, 2019The Systems Group Named a Top Specialty Contractor

Arkansas Company #350 in 2019 ENR Top 600 Specialty Contractors Ranking El Dorado, Ark., October 2019 – The Systems Group (tsg.bz), a leading specialty contractor serving the industrial market with a focus on steel mills, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking report released by Engineering News-Record (ENR), a

1510, 2019Systems Spray-Cooled receives an order from Europe for a new Spray-Cooled™ EAF Roof and Elbow

October 2019, Nashville, TN --Industeel Belgium sa (“Industeel”) has placed an order for a new Spray-Cooled™ Electric Arc Furnace (EAF) Roof and Elbow with Systems Spray-Cooled. The 2020 design-build project includes a new EAF Roof, Elbow, engineering, laser scans, and accompanying equipment that will replace its existing tubular equipment. The full scope, in conjunction with

204, 2018The Systems Group is Making a BIG Economic Impact in Southern Arkansas

The Systems Group is Making a BIG Economic Impact in Southern Arkansas April 3, 2018, El Dorado, Arkansas - The Systems Group (TSG) is making a BIG difference in their hometown, manufacturing Spray-Cooled™ furnace equipment used in the steel making industry, one that in turn drives our national economy. TSG started in El Dorado in

2407, 2017Ovako Hofors Puts Safety at the Forefront with the First Spray-Cooled™ EAF Roof in the Nordic Region

July 24, 2017, El Dorado, Arkansas – Swedish steel producer Ovako has awarded Systems Spray-Cooled the contract to modernize and increase safety on their Electric Arc Furnace (EAF) with the first Spray-Cooled™ roof in the Nordic region, located at their bar, billet, tube, and rings facility in Hofors, Sweden. After first being exposed to Spray-Cooled

1301, 2017Systems Spray-Cooled News Flash: AIST Jan Front Cover, Safety First Article, & NYS Technical Article

Front Cover: Initial EAF Heat at Big River Steel of Osceola, AR Systems Spray-Cooled is proud to announce the appearance on the front page of the January 2017 AIST Iron & Steel Technology industry magazine. On the cover is Spray-Cooled's newest 165-ton furnace going into service at Big River Steel in Osceola, AR. Congratulations to

908, 2016The Systems Group Introduces Self-Maintaining Air Cleaner for Steel Mill Transformer Vaults, Motor Control Rooms and Other Critical Spaces

August 9, 2016, El Dorado, Arkansas -- The Systems Group (www.tsg.bz), a diverse group of companies engaged in construction, maintenance and products for steel manufacturing and other heavy industry, has introduced the first auto-cleaning air filtration system for steel mill transformer vaults, motor control rooms, air compressor systems, engine intakes and other critical spaces. The

1501, 2016Systems Spray-Cooled Makes AIST Front Cover

Systems Spray-Cooled™ Makes AIST Front Cover El Dorado, Ark., January 15, 2016 –Systems Spray-Cooled is proud to announce the appearance on the front page of the January 2016 AIST Iron & Steel Technology industry magazine. On the cover is a new single-bucket charge upper and lower electric arc furnace shells (6,500 ft3/184 m3) going into service at

2411, 2015The Systems Group Named a Top Specialty Contractor

Arkansas Company Advances to #268 in 2015 ENR Top 600 Specialty Contractors Ranking El Dorado, Ark., November 24, 2015 – The Systems Group (tsg.bz), a leading specialty contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual ranking report released by Engineering News-Record

2010, 2015The Systems Group Donates Steel Structure for Engineering

“The Systems Group is honored to be part of helping the engineering students at Arkansas State,” Morgan explained. “The teaching sculpture allows teachers to show students the actual connections of structural beams used in commercial and industrial buildings and equipment structures. Systems is dedicated to helping create the next generation of people to help further the steel industry.”

1408, 2015The Systems Group Donates Quarter Million For Training Center Construction

El Dorado, AR, August 14, 2015: Representatives of The Systems Group and the Hays family donate $250,000 in honor of Charles A. Hays to help fund construction of the new South Arkansas Community College Advanced Manufacturing Training Center, which will break ground later this month. Hays, who founded The Systems Group more than 40 years

1407, 2015Updated Spray-Cooled™ Equipment Offers Enhanced Safety, Longevity, Uptime

El Dorado, AR, July 14, 2015: Systems Spray-Cooled™ (spraycooled.tsg.bz), which manufactures a line of non-pressurized, non-evaporative water-cooling equipment for the global metal and mineral industries, has updated its technology to incorporate several performance enhancements and new patented features that result in greater safety, equipment longevity and operational uptime.

2606, 2015Pagan Passes CWI Test

El Dorado, AR, June 26, 2015: Systems Fab & Machine in El Dorado, AR. proudly announces and congratulates one of their employees, Robert Pagan, for passing his CWI test in Memphis, TN. last week.

1506, 2015Summer Concert Series Downtown El Dorado AR

El Dorado, AR, June 15, 2015: Main Street El Dorado is proud to present the Murphy USA Summer Concert Series summer schedule. The concert series is free to the public and will feature national music artists performing outside on Union Square in the heart of historic downtown El Dorado. The concerts

1006, 2015Le Bonheur Charity Golf Tournament, Nucor Hickman

Hickman, AR, June 2015: The Systems Group participated recently in the Nucor Hickman charity golf tournament and auction benefitting the Le Bonheur Children’s hospital. It was June 7 & 8. Sunday evening June 7 was the auction and Systems donated $17,000 plus sponsoring a golf hole. Tony Lollar and Lee Morgan were there

3005, 2015Nucor Steel and Relay For Life Award

Decatur, Al, April 2015: Systems’ representative, Bud Christianson, accepts award from Nucor Steel’s Executive Vice President, Ladd Hall, recognizing the $10,000 donation by The Systems Group to the American Cancer Society’s Relay for Life in Decatur, AL.

2605, 2015The Systems Group Expands, Adds Fourth Division

El Dorado, Ark., May 26, 2015 – The Systems Group (TSG), (https://tsg.bz), a diverse group of companies engaged in construction, maintenance and products for steel manufacturing and other heavy industry, has just completed a corporate expansion which includes the addition of a new business unit and the re-naming of another.

912, 2014Lee Morgan Named President of The Systems Group

El Dorado, AR, December 9, 2014 – The Systems Group (TSG), (www.tsg.bz), a diverse group of companies engaged in fabrication, plant maintenance and construction for steel mills, foundries, metal processing plants, petrochemical plants and manufacturing facilities, announces that Lee Morgan has joined the company as its new president.

2011, 2014Systems Contracting Advances 10 Positions – ENR Top 600 Specialty Contractors

Systems Contracting advances 10 positions to #318 in the 2014 Engineering News-Record’s Top 600 Specialty Contractors. El Dorado, Ark., November 20, 2014 – Systems Contracting Corporation, a leading contractor serving the industrial, municipal and commercial construction markets, has been named one of the Top 600 Specialty Contractors nationwide in an annual

1302, 2014Systems Fab & Machine (American Steel Company) Completes CSA Certification